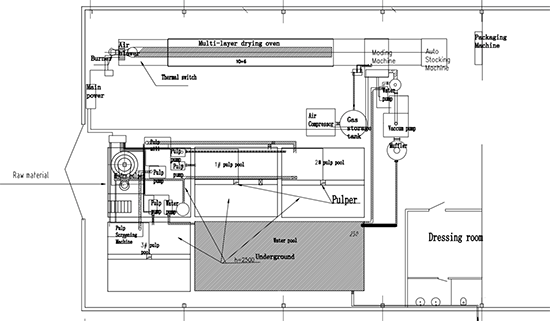

FLOWCHART OF EGG TRAY PRODUCTION LINE

-

The complete egg tray plant includes basically 3 sections: pulping section, molding section and drying section. Some assistant equipments are required as well such as air compressor, vacuum pumps, hot pressing machine, burners, etc.

- The pulping section:

-

- Feed clean water into hydraulic pulper to it's 60%~70% level, scale proper weight of waste paper and load inside the hydra pulper. Color dyes can be added as well simultaneously.

- The waste paper pulp stays 20~40 minutes inside the pulper, depending on paper fibre, and then pumped into vibrating screener. Water is added during the screening for pulp dilution. The impurities such as nails, metal pieces, plastic films, etc will be removed.

- The pulp goes to NO.1 pool before entering pulp miller where it will be refined into average consistency. After grinding, the pulp goes to NO.2 pool before entering the egg tray molding machine.

- Another NO.3 pool can be built as well as stand by pools, or for extra pulps. Chemicals to be added include aluminum sulfate and other water proof agents.

- The molding section

- Start the rotary egg tray molding machine and pump the pulp inside, the extra pulp will flow back to pool NO.1 automatically.

- Turn on vacuum pump for vacuum production. Water for vacuum pump operation should be clean and circulated. The water separated by the vacuum pump from the molding machine will flow to the pulp pool for another circulation.

- For each stroke of egg tray molding, water will be sprayed out from the nozzles to clean the molds. It's a very important unit which not only cleans the mold but also removes extra burrs on the egg tray, making sure the egg tray produced has a smooth edge.

- The drying section:

-

With each stroke of egg tray molding, the transfer arm move the wet trays into the chain converyor which will enter the drying tunnel for the removal of moist. There are two types of drying oven, multi-layer type and single layer type.

- Counting, Reshaping and Packaging:

-

At the end of the drying tunnel, there is an automatic counting device to account trays produced. Reshaping process are required for products as egg box and other stuff which requires flat apperance. The trays produced are finally packaged by plastic films or carton box.

Español

Español English

English